Clamping force testing instrument solution

Product defective rate dilemma :

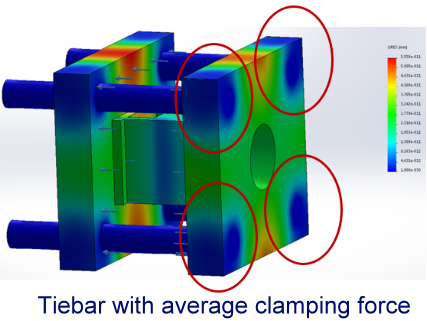

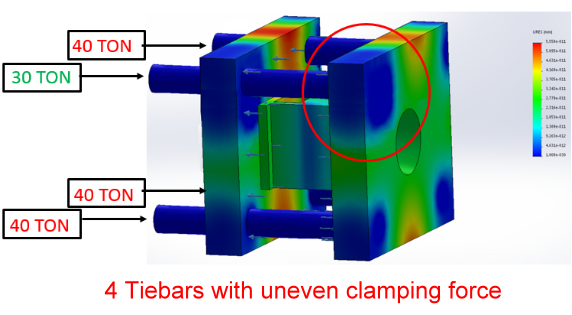

The current injection molding or die-casting of bad products, such as the burr or die-casting metal liquid overflow, resulting in improved product non-performing rate, most of the problems are mold PL surface problems, first of all if the mold itself is no problem, and most of the problems are The tension of the four Tie bars of the die-casting machine or the injection molding machine is not even, and the PL surface of the die-bearing force is also not even. |

|

|---|

| ||

|---|---|---|

History of development:

At present, the injection molding machine manufacturers and die-casting plant common problems common, that is, the mechanical TieBars may not be averaged; and set the clamping force and the real clamping force is not the same, it will lead to mechanical production process, High load or overload conditions for the production process; but under these conditions there will be some problems, that is, will result in machine performance loss and improve the machine TieBar easy to break the risk of the relative mold will be damaged, the lock Mold too much will lead to poor mold exhaust, affecting the accuracy of the machine's finished product. In view of this, how to make the injection molding machine TieBar average force, and fast and accurate way to replace the traditional scale time-consuming calibration, the use of more sensitive calibration technology to improve efficiency. "Die clamping force measurement technology" uses metal due to external forces caused by structural deformation, by the sensor to detect the deformation of the resulting weak signal, and then by the amplification and signal compensation, and then quantify the accurate and useful signal. In addition to the combination of sensor fixture design technology, to achieve the measurement reproducibility of less than 0.5%. Accurate control of equipment clamping force changes, lay the cornerstone of intelligent technology development, improve product quality and yield increase, reduce the traditional detection time 70%.

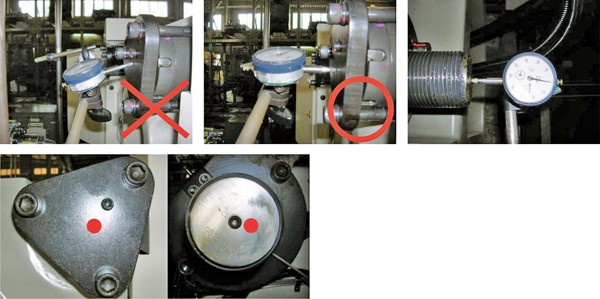

Traditional calibration method:

Currently, the traditional TieBar adjustment method (pictured above) must use a dial indicator to vertically detect the center of one of the TieBars and start the mold to measure the change in the TieBar. There must be four TieBars at the front and rear that need to be measured. At least 4 dial indicators are needed to understand the clamping force endured by each TieBar (the accuracy is relatively rough). After adjusting one TieBar, the other three TieBars will be affected by the average force of the TieBar and change the pulling force. It is impossible to quickly observe the data of the four TieBars. It is a waste of time and energy when adjusting.

New product improvements are available

| Heryun Technology develops an easy-to-use clamping force measuring instrument: Model: HY CD4 | ||

|---|---|---|

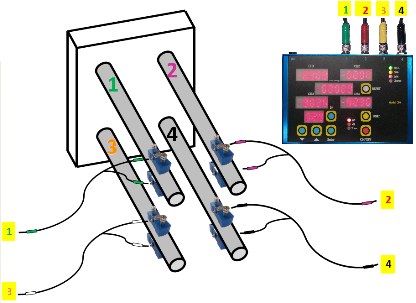

High precision tensile force sensor for the latest generation of developed products, complete, sophisticated and rapid measurement methods, adopt the intuitive measurement method, the sensor has two super-magnet components, adsorption in the TieBar and measure the deflection (deformation) compensation pull The extension or load. |

| |

| ||

The overall lightweight ABS outer box design is easy to extract, durable and easy to store. The careful design makes the whole set lightweight and improves the accuracy of the instrument. All sensors are interchangeable. | ||

Each sensor has 2 built-in magnets. The two sensors are 180 degrees opposite each other and are connected to a dedicated display. There are 4 Tiebars with a total of 8 sensors. It also has an intuitive measurement and observation method to observe the data of all Tiebars, including their positions, data, etc. Easy to adjust, it is convenient to observe the problem of adjusting one Tiebar's influence on the tension of other Tiebars, reduce adjustment time, and display accurate data, and the average (deformation) or total (tonage) data displays standard data. | ||

|

| |

Use a dedicated disassembly tool and level calibrator for easier installation and safe disassembly. | ||

Using eight CD4 sensors at Teibar, show a single Tei bar data / average strain (amount of deformation) / Total Tons, kN, respectively.

Various Ø diameters can be input for calculation and micro-adjustment, and the displayed strain amount (µƐ) is 10µƐ=1 bar. There is also a manual reset for mold opening to ensure that the reproducibility of data for each mold is accurate.Professional 4 Port monitor, built-in lithium battery charging system and voltage instructions, charging 10 minutes to use. |

| |

Market analysis:Model: HY-CD4 insists on using the same Swiss data technology and core electronic components with the same Swiss technology specifications, and is 100% developed and manufactured in Taiwan, which is different from other brands' considerations of profit and cost balance. With low price, quality and service as the top priority, it has been favored by leading machinery manufacturers. |

Cost considerations:Due to the high requirements for quality, data, durability, etc. of this product, the high cost is due to the accuracy of measurement data and quality control. The core uses electronic components from the United States, Germany, and Japan, so the appearance and appearance are not gorgeous and high-quality. The route only requires considerations of durability and practicality. |

Competitiveness:At present, the quality requirements of domestic products are increasing, and price competitiveness is closely related to the future development of the company. In terms of the sustainable management concept of the market, how to convert costs into maximum commercial benefits, the most important part of the manufacturing industry is working hours and quality. Rate.Many manufacturers have used our measuring instruments to monitor products added to the production sequence. Any make and model can be repaired, and technical and maintenance after-sales services are also guaranteed. |