page2

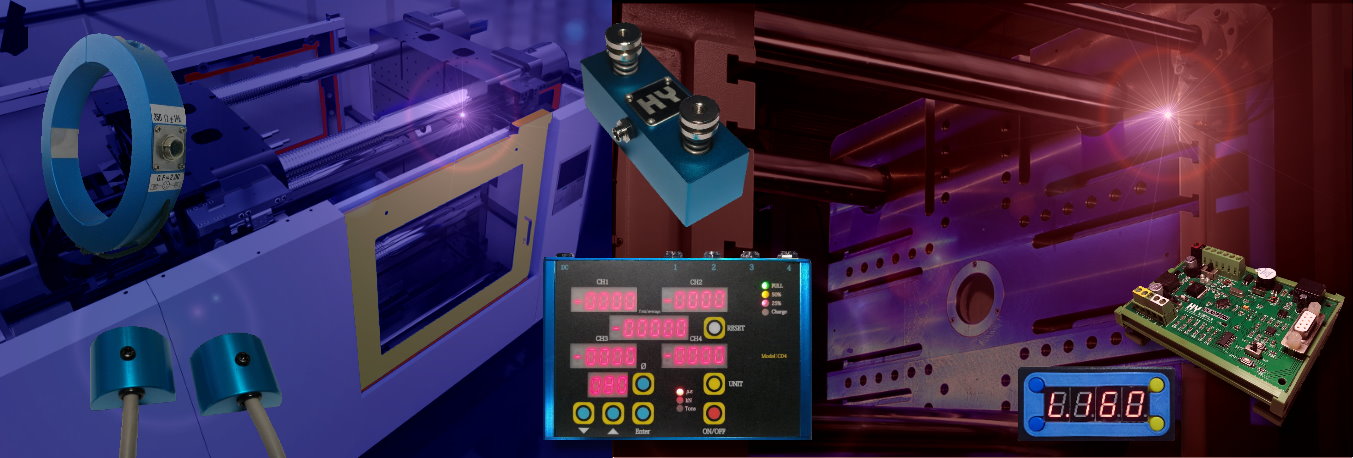

Heryun Technology Co., Ltd. is a developer and manufacturer of industrial machinery clamping force sensors.

Launched HY-CD4, a high-precision clamping force/tensile force detection instrument suitable for industrial machinery such as die-casting machines, injection molding machines, hydraulic presses, and mold clamping machines.

The absolute accuracy of Heryun Technology's high-precision testing instrument products is less than ±1%.

The products are developed based on the principles of simple use, quality, durability and safety.

They can effectively save costs and increase profits for customers. Since the launch of the products, after continuous testing Stress testing and improvements have been highly recognized by the industry and deeply trusted by customers.

In order to deepen the market, we will continue to invest in the research and development of more high-precision instrument products such as testing equipment and monitoring equipment that are beneficial to the application of the industrial machinery industry, and continue to provide customers with the most complete after-sales service with the goal of price, quality and service. ,

Comprehensively enhance corporate value and achieve the goal of sustainable management.

Heryun Technology Co., Ltd. is a developer and manufacturer of industrial machinery sensors.

It has launched HY-CD4, a high-precision clamping force/tensile force detection instrument for industrial machinery such as die-casting machines, injection machines, hydraulic presses, and mold clamping machines.

Long-term research on Tiebar tensile force and mold clamping force has been conducted for more than ten years.

The absolute accuracy of Heryun Technology's high-precision testing instrument products is less than ±1%.

The products are developed based on the principles of simplicity of use, quality, durability and safety.

They can effectively save costs and increase profits for customers. Since the launch of the products, after continuous repetition Testing and improvement have been highly recognized by the industry and deeply trusted by customers.

In order to deepen the market, we will continue to invest in the research and development of more high-precision instrument products such as testing equipment and monitoring equipment that are beneficial to the application of the industrial machinery industry, and continue to provide customers with the most complete after-sales service with the goal of price, quality and service.

Comprehensively enhance corporate value and achieve the goal of sustainable management.

R&D, manufacturing (100% made in Taiwan), testing, calibration and maintenance of clamping force measuring equipment and monitoring equipment.

HY-CD4 clamping force testing instrument is discounted by 10% from now on (until February 31, 2024).

Industry leaders are welcome to let us provide you with quotations.

page3

Clamping force Instruments

High precision tensile force sensor for the latest generation of developed products, complete, sophisticated and fast measurement methods. Intuitive measurement method: sensing element with two super magnets to measure the deflection (deformation) compensation rod extension or load. |

|

|

Simple and easy to disassemble, magnetic sensor, super strong suction and stable Adsorbed on the Tiebars and detect the stretching amount of the Tiebars. |

The digital display is easy to operate, corresponds to the Tiebar position, and provides an intuitive detection method.

●Can be used for different diameter Tiebars measurements.

●It is magnetically mounted on the Tiebar for easy disassembly and use at any time.

●Each Tiebar uses two sensors to compensate for the deviation of Tie Bars bending.

●Advanced all-electronic technology,High Accuracy <1%。

●Take the strain µƐ (10µƐ=1 bar).

●Quickly solve the industrial use of the injection machine, die-casting machine manufacturers and machinery refurbished use.

●Quickly adjust the average pulling force of 4 Tiebars to prevent column breakage and protect the mold.

●Handheld digital operation and water-proof display panel for easy operation.

●The monitor has a built-in lithium battery and voltage light display (charger included).

●Lightweight ABS outer box.

●It comes with 4 Y-shaped transmission lines to prevent EMI signal interference, which is convenient for connecting the sensor and the display.

●Special disassembly tool and level calibration.

●Lightweight 6kg.

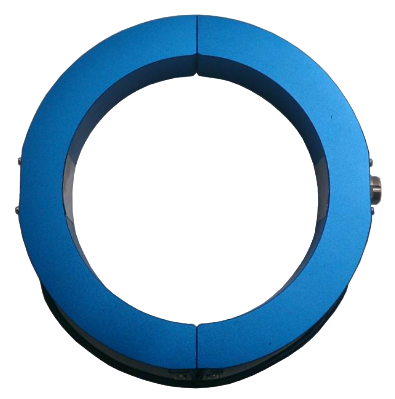

Clamping force Monitoring

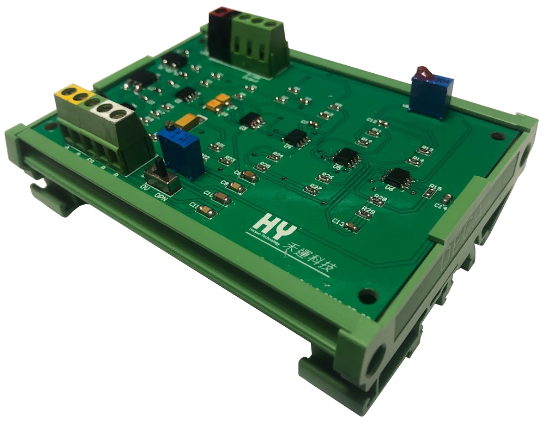

High precision tensile force ring gauge sensor developed products, providing Tiebars tensile force load monitoring use.

The ring gauge sensing element is torsion-locked to the Tiebars to sense the strain signal, and can be used with the AMP2 amplifier to output the signal to the PLC interface to calculate the clamping force data through programming. The definition is displayed on the PLC human computer.

The ring-type sensor can also be connected to AMP_D1 and the display to directly display the clamping force data without going through the PLC interface.

Various ring gauge diameter sizes are customized to match the Tiebars Ø diameter of various die-casting machines or injection machines.

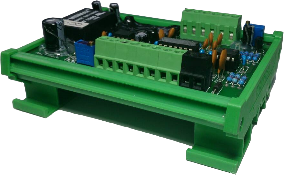

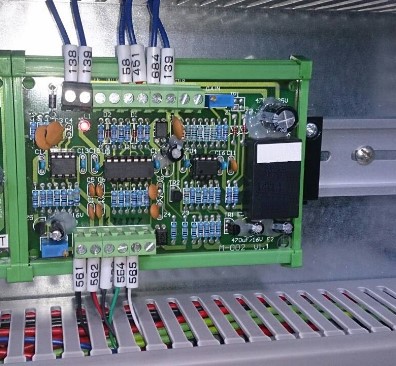

Dedicated analog amplifier for ring gauge sensors, used for Tiebars tensile force load monitoring.

0~10V linear voltage value comparison operation can be defined in the human-machine PLC clamping force value.

Automatically receive the mold opening signal Reset (the signal +24V or 0V is provided by the machine as the mold opening signal output).

Provides Zero correction to make the mold closing data more accurate after Reset.

Aluminum rail design, mold opening and closing light indicators, suitable for electric control box installation.

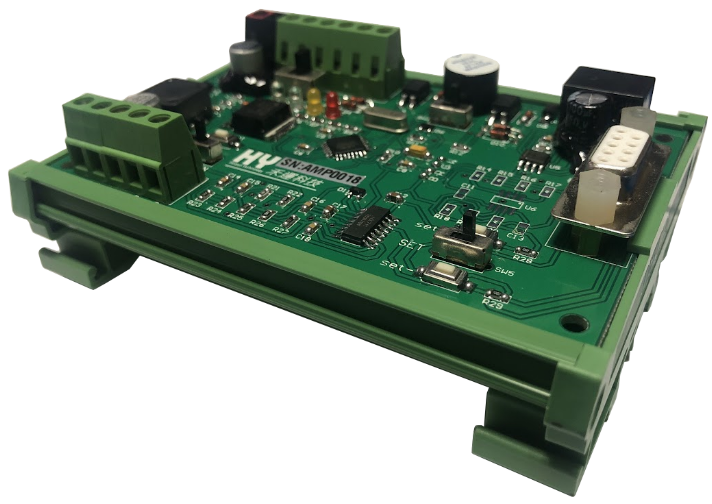

Special digital amplifier for ring gauge sensor, providing Tiebar tensile force load monitoring.

Convert the strain detected by the sensor into Mod-bus signal and output it to PLC or HMI.

The signal includes tonnage, kN, Tiebar diameter, and interruption.

Automatically receive the mold opening signal Reset (the signal +24V or 0V is provided by the machine as the mold opening signal output).

Mod-bus signals allow PLC to customize tonnage display and upper and lower limit alarms.

In addition, a special meter can be directly installed to directly display the tonnage and upper and lower limit alarms (no need to connect to PLC or HMI interface).

Provide Tiebar diameter adjustment and upper and lower limit setting adjustment, and calculate clamping force.

Large panel lockable design with upper and lower limit setting functions for easy installation, setting and monitoring

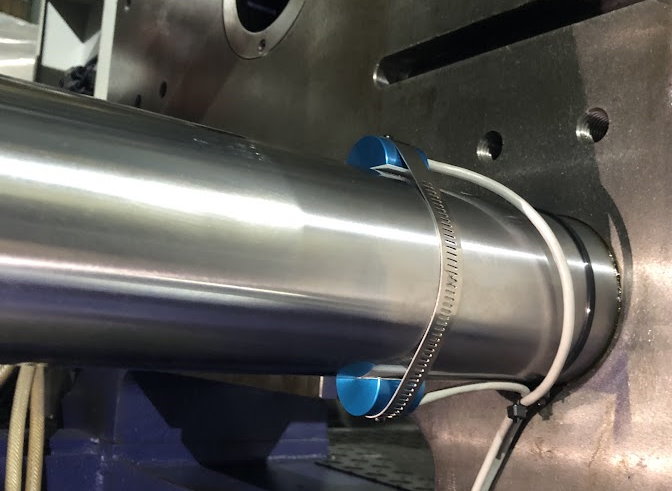

A high-precision tensile force steel belt sensor product is developed to provide Tiebar tensile force load monitoring.

Various steel belt diameter sizes are customized to match the Tiebar diameter size.

Various steel belt diameter sizes are customized to match the Tiebar diameter size.

Convert the strain detected by the sensor into a voltage signal.

The amount of strain corresponding to the output voltage is linear.

0~10V linear voltage value comparison operation can be defined in the human-machine PLC clamping force value.

Provides Zero correction.

Aluminum rail design, mold opening and closing light indicators, suitable for electric control box installation.

Clamping force testing instrument solution

|

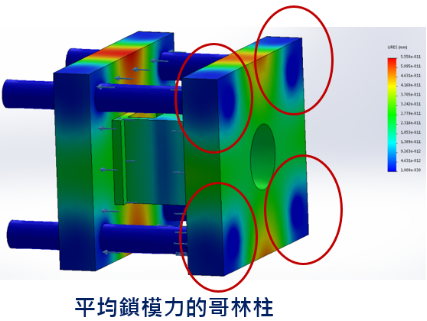

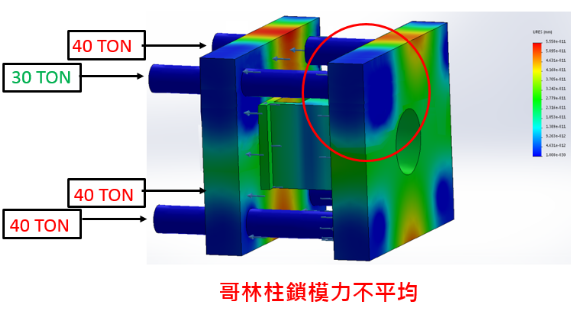

The current injection molding or die-casting of bad products, such as the burr or die-casting metal liquid overflow, resulting in improved product non-performing rate,most of the problems are mold PL surface problems。 First of all if the mold itself is no problem, and most of the problems are The tension of the four Tie bars of the die-casting machine or the injection molding machine is not even, and the PL surface of the die-bearing force is also not even. |

At present, the injection molding machine manufacturers and die-casting plant common problems common, that is, the mechanical TieBars may not be averaged.

And set the clamping force and the real clamping force is not the same, it will lead to mechanical production process, High load or overload conditions for the production process.

But under these conditions there will be some problems, that is, will result in machine performance loss and improve the machine TieBar easy to break the risk of the relative mold will be damaged, the lock Mold too much will lead to poor mold exhaust, affecting the accuracy of the machine's finished product.

In view of this, how to make the injection molding machine TieBar average force, and fast and accurate way to replace the traditional scale time-consuming calibration, the use of more sensitive calibration technology to improve efficiency.

"Die clamping force measurement technology" uses metal due to external forces caused by structural deformation, by the sensor to detect the deformation of the resulting weak signal, and then by the amplification and signal compensation, and then quantify the accurate and useful signal.

In addition to the combination of sensor fixture design technology, to achieve the measurement reproducibility of less than 0.5%. Accurate control of equipment clamping force changes, lay the cornerstone of intelligent technology development, improve product quality and yield increase, reduce the traditional detection time 70%.

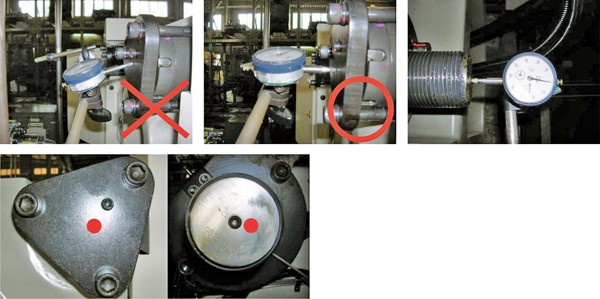

Currently, the traditional TieBar adjustment method (pictured above) must use a dial indicator to vertically detect the center of one of the TieBars and start the mold to measure the change in the TieBar.

There must be four TieBars at the front and rear that need to be measured. At least 4 dial indicators are needed to understand the clamping force endured by each TieBar (the accuracy is relatively rough).

After adjusting one TieBar, the other three TieBars will be affected by the average force of the TieBar and change the pulling force.

It is impossible to quickly observe the data of the four TieBars. It is a waste of time and energy when adjusting.

Clamping force measuring instrument: |

High precision tensile force sensor for the latest generation of developed products, complete, sophisticated and rapid measurement methods. The best handheld sensor for optimal installation, adjustment and maintenance. |

|

|||

|

|

|||

| The overall lightweight ABS outer box design is easy to extract, durable and easy to store. The careful design makes the whole set lightweight and improves the accuracy of the instrument. All sensors are interchangeable. | ||||

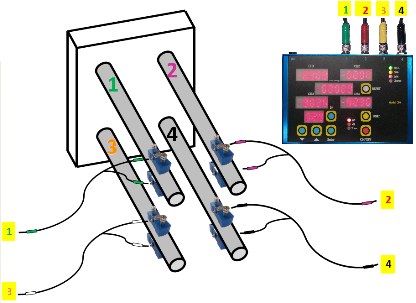

Each sensor has 2 built-in magnets. The two sensors are 180 degrees opposite each other and are connected to a dedicated display. There are 4 Tiebars with a total of 8 sensors. It also has an intuitive measurement and observation method to observe the data of all Tiebars, including their positions, data, etc. Easy to adjust, it is convenient to observe the problem of adjusting one Tiebar's influence on the tension of other Tiebars, reduce adjustment time, and display accurate data, and the average (deformation) or total (tonage) data displays standard data. |

||||

|

|

|||

| Use a dedicated disassembly tool and level calibrator for easier installation and safe disassembly. | ||||

Using eight CD4 sensors at Teibar, show a single Tei bar data / average strain (amount of deformation) / Total Tons, kN, respectively. |

|

|||

| Professional 4 Port monitor, built-in lithium battery charging system and voltage instructions, charging 10 minutes to use. | ||||

Model: HY-CD4 insists on using the same Swiss data technology and core electronic components with the same Swiss technology specifications, and is 100% developed and manufactured in Taiwan, which is different from other brands' considerations of profit and cost balance. With low price, quality and service as the top priority, it has been favored by leading machinery manufacturers.

Due to the high requirements for quality, data, durability, etc. of this product, the high cost is due to the accuracy of measurement data and quality control.

The core uses electronic components from the United States, Germany, and Japan, so the appearance and appearance are not gorgeous and high-quality.

The route only requires considerations of durability and practicality.

At present, the quality requirements of domestic products are increasing, and price competitiveness is closely related to the future development of the company.

In terms of the sustainable management concept of the market, how to convert costs into maximum commercial benefits, the most important part of the manufacturing industry is working hours and quality and yield ratio.

Many manufacturers have used our measuring instruments to monitor products added to the production sequence.

Any make and model can be repaired, and technical and maintenance after-sales services are also guaranteed.

page4

Contact Us

Heryun Technology Co., Ltd.

Engineering Department Email![]()

International Sales Department Email![]()

Heryun Service Email![]()

Location

![]() Heryun Technology Co., Ltd.

Heryun Technology Co., Ltd.

Address:1F., No. 389, Sec. 6, New Taipei Blvd., Taishan Dist., New Taipei City 243092 , Taiwan (R.O.C.)

E-mail:service@heryun.com.tw

Link

| Link | Address |

| KNCTaiwan | http://www.knc.com.tw |

| FUYASHI | http://www.fuyashi.com |

| KatoTech | http://www.keskato.co.jp |

| Haufu Car Media | http://www.haufu.com.tw |

![]()